Blog

Investment Casting with Aluminum Alloys

For many manufacturers, utilizing investment casting with aluminum alloys offers significant benefits over other metals. One of the biggest potential benefits is that aluminum is about one-third the weight of steel. It is also completely impermeable to odor and ...

Centrifugal vs. Investment Casting

Centrifugal and investment casting are two different processes utilized for making near-net-shape, high-quality components. The key difference is that investment casting relies on gravity to flow the molten alloy throughout the mold, while centrifugal casting employs...

Casting Size Matters

When choosing a process for producing your parts, keep in mind that the casting size matters; particularly die casting. Die casting certainly has some features that could be appealing for certain applications, however, it is typically more limited by the casting size...

Choose Your Foundry Carefully for Aluminum Casting

Specialized alloys offer invaluable benefits in many cases, but it is important to choose your foundry carefully for aluminum castings. That is because utilizing aluminum requires extensive expertise, capabilities and experience. Consider the following: Molten...

Tooling Cost for Investment Casting

A frequently asked question is what is the tooling cost for investment casting? There is no question that investment casting requires a significant tooling cost at startup. But that cost brings benefits that more than compensate for the initial outlay of capital. For...

Investment Casting with Duplex Stainless Steel

When manufacturers have specialized needs, it is a good idea to consider investment casting with duplex stainless steel. Some applications require either austenitic (non-magnetic) or ferritic (magnetic) stainless steel alloys. These duplex stainless steels have...

Investment Casting Reduces Waste

If you’re focusing on increasing production efficiency and cutting costs, you should know that investment casting reduces waste. Because it is a near-net-shape process, investment casting parts require little or no machining and finishing work. It can be significantly...

Four More Defects to Avoid

A foundry with highly skilled, experienced investment casting professionals can prevent the four casting defects discussed in our previous post. Following are four more to avoid: Runout – is when molten alloy seeps out of the mold while it is filled. It can...

Avoid Investment Casting Defects

Investment casting may seem like a fairly simple process on the surface, but it requires significant experience and expertise to avoid investment casting defects. Here are four common types of defects: Misrun – occurs when the molten alloy does not completely...

Investment Casting Quiz Answers

If you took the short investment casting quiz we presented in our last post (dated ________), we hope you did well. To find out, here are our investment casting quiz answers: How long ago did people begin using investment (or lost wax) casting? 1,000 years?...

Investment Casting Quiz

Do you think you’re pretty knowledgeable about investment casting? See if you can correctly answer the following five questions: How long ago did people begin using investment (or lost wax) casting? 1,000 years? 2,500 years? 5,000 years? What is the PED (European...

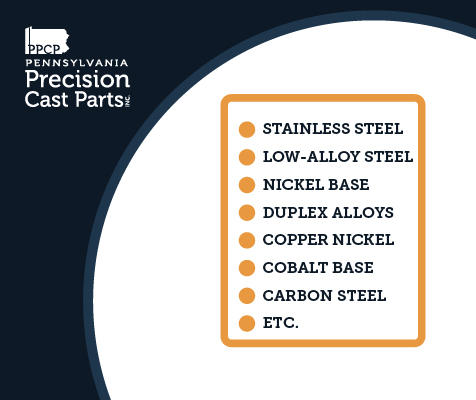

Alloys for Investment Casting

While common alloys are often appropriate for a wide range of applications, some have special requirements, which is why PPCP offers an extensive selection of specialized alloys for investment casting. Here are categories of alloys that are available: Stainless...

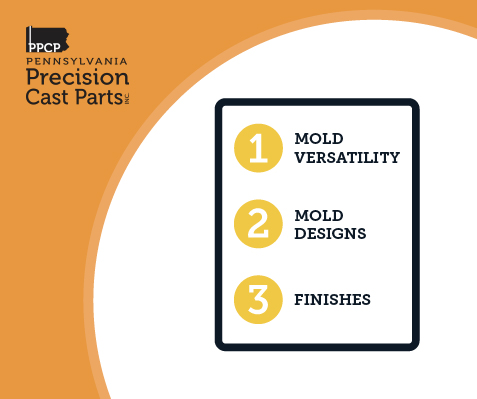

Investment Casting over Sand Casting

When choosing a production process, many manufacturers select investment casting over sand casting because of its significant advantages. Consider these three important factors: 1 – Mold Versatility: Investment casting molds can accommodate more complex,...

Investment Casting Applications

Happy New Year! If you are starting off 2024 considering different manufacturing processes for your parts, you should know about the many and diverse investment casting applications. The investment casting process is extremely versatile and accommodating of a vast...

A PPCP Christmas Season Wish

During the year, we are all so focused on our many immediate priorities and concerns that we sometimes don’t take the time to remember the most important things like family, friends and partners. Every year during the Christmas and holiday season, we at PPCP like to...

End-of-Year Investment Casting Value Checkup

Before you start the new production year, it’s a good idea to do an end-of-year investment casting value checkup. There are many important considerations when evaluating the value you are receiving from your parts supplier. Some are clearly tangible and measurable....

End-of-Year Foundry Checkup

Is your investment casting partner the best one for your needs? Find out with an end-of-year foundry checkup. While there are many capabilities and characteristics that determine whether your foundry is the right one for you, these are among the most important: ...

End-of-Year Investment Casting Checkup

As we come to the end of 2023, it’s a great time to do an end-of-year investment casting checkup. Many manufacturers are satisfied with the quality of their precision cast parts, not realizing that they could be better. Without knowing it, some may be missing valuable...