Blog

End-of-Year Foundry Checkup

Is your investment casting partner the best one for your needs? Find out with an end-of-year foundry checkup. While there are many capabilities and characteristics that determine whether your foundry is the right one for you, these are among the most important: ...

End-of-Year Investment Casting Checkup

As we come to the end of 2023, it’s a great time to do an end-of-year investment casting checkup. Many manufacturers are satisfied with the quality of their precision cast parts, not realizing that they could be better. Without knowing it, some may be missing valuable...

Giving Thanks

As we get ready to watch the Thanksgiving Day football games, enjoy the parades, and feast on bountiful turkey dinners with friends and loved ones, we should also take time to give thanks for our good fortune and blessings. At PPCP, we never forget how important our...

Investment Casting Expertise

One of the most important factors in ensuring the quality of your precision cast parts is your foundry’s investment casting expertise. It takes years of training and experience, plus ongoing learning about processes and materials to gain and hone the ability to...

Questions About Investment Casting?

The process may seem straightforward on the surface, but many people have questions about investment casting, how it works and if it’s right for their applications. At PPCP, we have the answers, whether it’s concerning the process itself, the alloys it can...

Key Advantages of Investment Casting

When deciding which production process to use for your parts and components, it is helpful and beneficial to know about the key advantages of investment casting. They add up to exceptional quality, reliability and value. Consider these investment casting advantages:...

Investment Castings for Pumps

If you have wondered if investment casting is right for pumps, the answer is a resounding “yes”! Whatever your industry or application, investment casting can almost certainly meet your needs better than many other processes. It can accommodate numerous alloys, from...

Investment Casting for Specialized Hardware

When you need unique parts, you can rely on investment casting for your specialized hardware needs. Investment casting offers the versatility and capabilities to produce a virtually endless range of very small to very large parts with highly diverse characteristics....

Investment Casting for Gas and Air Compressors

Many manufacturers have discovered the extensive benefits of investment casting for gas and air compressors. These devices often demand extremely precise tolerances and specifications to properly perform in vital applications. Investment casting is ideal for making...

Investment Casting for Process Controls & Instrumentation

If you manufacture components that require very high levels of precision, you should consider investment casting for your process controls and instrumentation. Unlike many other processes, investment casting can achieve the reliability and accuracy you need for even...

Investment Casting Shell Quality

Investment casting shell quality is a very important factor in producing top-notch, reliable parts. There are numerous potential causes of less-than-optimal shells that are controllable by the right foundry staff and processes. Shells are made by repeatedly dipping...

Optimize Aluminum Castings

While aluminum is an extraordinarily beneficial alloy for many applications, it takes much expertise and care to optimally produce aluminum castings. During the production process, the foundry staff must ensure that the molten aluminum does not experience degradation...

Alloy Casting Temperature Requirements

Casting specifications may require specialized alloys that offer highly desirable properties. They may also have widely varying alloy casting temperature requirements. It is very important for your foundry to have the proper equipment and staff expertise to optimally...

Die Casting Size Limitations

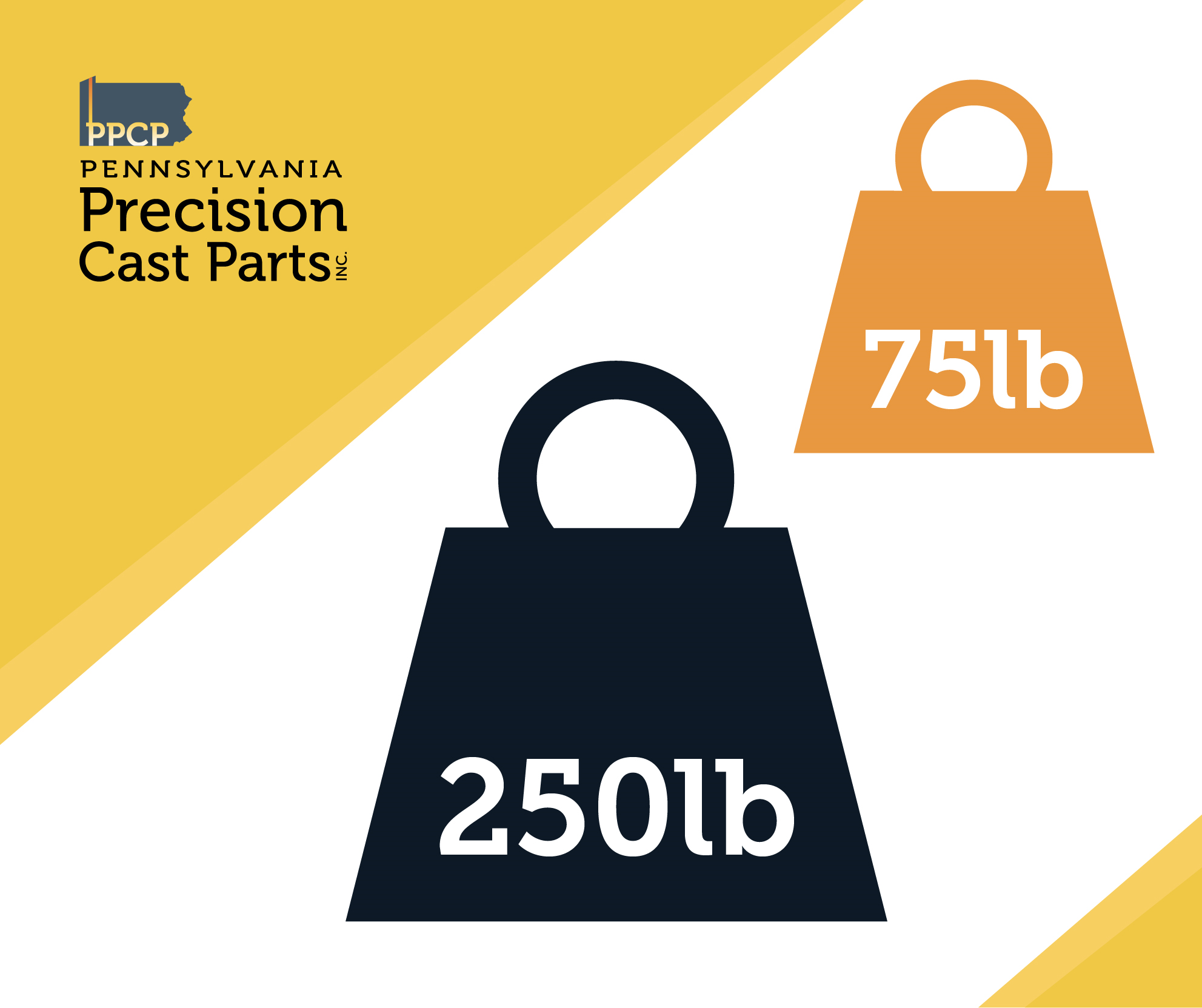

If you’re a manufacturer considering different options for casting your parts, you should be aware that die casting can offer some beneficial features, but it also has some drawbacks, like size limitations. Typically, die casting can accommodate parts that weigh up to...

Zero Days Lead Time Order for Investment Castings

To save time and money, many manufacturers are opting for PPCP’s zero days lead time ordering for investment castings. With this just-in-time delivery service, PPCP makes the pre-arranged number of castings on an established schedule and stocks them in the foundry...

Heat Treating Investment Castings

To achieve the optimal performance and characteristics of precision cast parts, foundries will often utilize the heat treating of investment castings. In many cases, this is a critical part of the production process. Once the casting has been set, it can be subjected...

Investment Casting Charpy Impact Testing

If it is important to determine how ductile or brittle an alloy may be in a finished part, metallurgists often utilize investment casting Charpy impact testing. Charpy impact testing utilizes a pendulum with a precise weight on the end. A notched, standard-size sample...

Precision Cast Parts with Fusible Alloys

Many manufacturers have discovered that investment casting is an excellent choice for producing precision cast parts with fusible alloys. Such alloys exhibit comparatively low melting points, below 450° F. This, along with other properties like good thermal...